Liqua-Tech Positive Displacement Flow Meters (PD Meters)

PD Meters (LPM) for gas terminals, gas supply installations, and road tankers.

Liqua-Tech Positive Displacement Flow Meters (PD Meters)

Liqua-Tech PD Flow Meters

The PD (Positive Displacement) flow meters from Liqua-Tech are available in a variety of sizes and configurations. PPTEC-ENERGY offers the complete range of Liqua-Tech meters and spare parts, ensuring reliable measurement and seamless integration into gas terminals, gas supply systems, and road tankers.

LPM-101

Application:

For applications requiring precise recording of fuel consumption and inventory control.

Operating Data:

- Flow rate: 12.0 – 68.0 L/min

- Maximum working pressure (MWP): 24 bar

- Connections: 3/4" or 1" NPT flanges

- Operating temperature: -23 °C to 52 °C

LPM-102

Application:

Reliable dispensing unit for low-LPF flow applications, ideal for retail fueling stations.

Features:

- Wide flow range: 12 – 68 L/min, the largest for meters of this type

- Self-contained design: includes vapor eliminator, filter, and differential valve

- Multiple configurations: registration in US gallons or liters

- Optional automatic temperature compensation

- ¾" or 1" flange connections available

- Full-Circle Quick-Vent® option: safe venting for maintenance and repair

- Compatibility: fully compatible with the Neptune 1” Type 4D-MD meter (dimensions and internal components)

Components:

- Vapor Eliminator

- Strainer (Filter)

- Differential Valve

- Optional: Trac-Bearing Chamber

Operating Data:

- Flow rate: 12.0 – 68.0 L/min

- Maximum Working Pressure (MWP): 24 bar

- Connections: Standard – suction side left, discharge side right; ¾" and 1" internal threads available

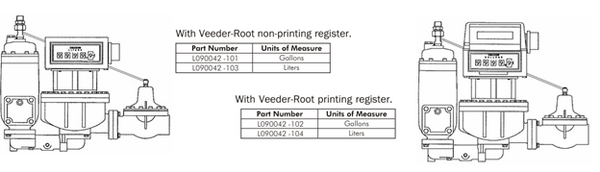

- Register: Veeder-Root; printer optional

- Temperature compensation: calibrated at 15 °C

- Operating temperature: -23 °C to 52 °C

LPM-200

Application:

Extremely reliable PD Meter for LPG trucks, LPG terminals, and LPG supply systems.

Features:

- Measuring chamber: hard-coated piston with special metal-oxide finish, hardened steel shaft, proven in thousands of installations

- Optional Trac-Bearing® chamber: higher accuracy, improved reliability, reduced maintenance

- Stabilized piston rotation ensures consistent linear measurement accuracy and lower wear

- Register: Veeder-Root, pressure or non-printing

- Optional configurations: gear plates, star drive, or spindle for electronic registering devices

- Exclusive Liqua-Tech adapter for Neptune-style interchangeable gears for easy calibration

Components:

- Vapor Eliminator

- Strainer (Filter)

- Differential Valve

- Optional: Trac-Bearing Chamber

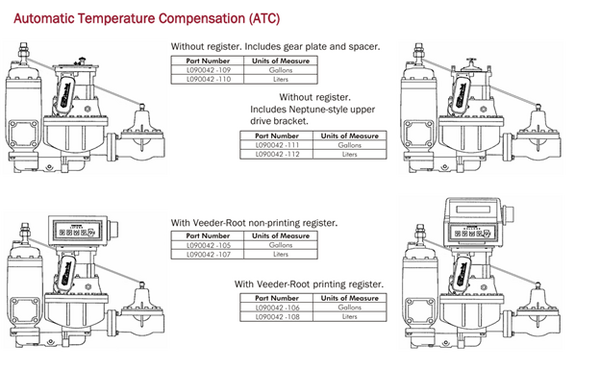

- Optional: Automatic Temperature Compensation

Operating Data:

- Flow rate: 75.0 – 380.0 L/min

- Maximum Working Pressure (MWP): 24 bar

- Connections: 2" NPT

- Register: Veeder-Root model 789002 (printing) or 788700 (non-printing) with VRA-Series Adapter

- Operating temperature: -23 °C to 52 °C

- Temperature compensation: calibrated at 15 °C