BLACKMER-PPTEC Compressor skids for LPG

BLACKMER compressors for LPG

BLACKMER LB-Serie – Kolben-Gaskompressoren

The Blackmer LB Series piston gas compressors offer high efficiency for the handling of propane, butane, and anhydrous ammonia. They are ideal for unloading rail tank cars and storage tanks, as well as for associated vapor recovery applications.

The single-stage piston gas compressors are designed for maximum performance and reliability, even under extremely demanding operating conditions. All pressure-bearing components are made of ductile iron, providing increased resistance to thermal and mechanical stresses.

The design emphasizes maintenance-friendly operation – all critical components are easily accessible, greatly simplifying servicing and upkeep.

LB Series propane compressors are available with:

• Liquid delivery rates up to 2,575 L/min

• Piston displacement volumes up to 212 m³/h

• Operating pressures up to 24.13 bar

|

BLACKMER compressors |

LB080 |

LB161 |

LB361 |

LB601 |

LB942 |

|

Connections:

|

|

|

|

|

|

|

Number of Cylinders |

1 |

2 |

|||

|

Piston Stroke, mm |

63 |

63 |

76 |

102 |

181 |

|

Hubvolumenstrom, m³/h |

13 |

28 |

58 |

100 |

200 |

|

Min suction pressure, bar |

0,21 |

||||

|

Max disharge pressure, bar |

23,1 |

31 |

|||

|

Motor, recomended, KW |

3,6 |

5 |

10 |

17-18 |

30-37 |

|

Weight bare compressor, kg |

68 |

96 |

177 |

330 |

380 |

|

Wedight skid, aprx, kg |

225 |

283 |

385 |

650 |

1200 |

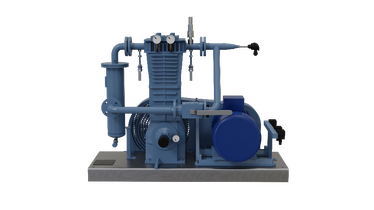

LB080-Serie – Kolben-Gaskompressoren

Model: LB081, LB082

The Blackmer LB080 Series piston gas compressors are the smallest models within the LB Series. They provide a delivery rate of 8.45 CFM at 825 RPM and are available in the LB081 and LB082 configurations.

The Blackmer LB080 Series compressors are particularly suitable for:

• Mobile applications

• Unloading small containers

• Vapor recovery applications

All Blackmer LB compressors feature a ductile iron cylinder head and cylinder, high-efficiency valves, steel pistons, self-adjusting piston rod seals, and other robust design elements. These ensure quiet and efficient handling of propane, butane, and anhydrous ammonia.

Even under extremely demanding operating conditions, the LB Series piston gas compressors offer an optimal combination of long-lasting high performance, energy efficiency, trouble-free operation, and low maintenance costs.

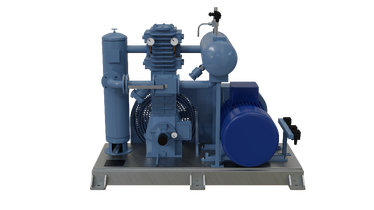

BLACKMER LB160-Serie – pistons gas compressors

Model: LB161, LB162

LB160 Series – Piston Gas Compressors

The Blackmer LB161 and LB162 compressors are two-cylinder piston gas compressors, delivering a capacity of 16.5 CFM at 825 RPM.

All BLACKMER LB compressors feature a robust and durable design:

- Cylinder head and cylinders made of ductile iron

- High-efficiency valves

- Steel pistons

- Self-adjusting piston rod seals

This construction ensures quiet and efficient handling of propane, butane, and anhydrous ammonia.

Even under the most demanding operating conditions, the LB Series compressors provide the ideal combination of:

- Consistently high performance

- Energy efficiency

- Reliable operation

- Low maintenance costs

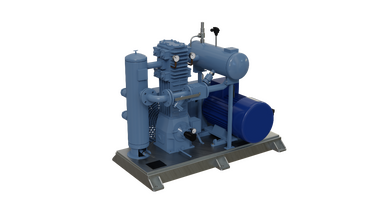

BLACKMER LB360-Serie – pistons gas compressors

Model: LB361, LB362

LB361 and LB362 – LB Series Oil-Free Piston Gas Compressors

The Blackmer LB361 and LB362 compressors are part of the LB Series of oil-free piston gas compressors. These are two-cylinder compressors delivering a capacity of 36 CFM at 825 RPM.

All LB compressors feature a robust and durable design:

- Cylinder head and cylinders made of ductile iron

- High-efficiency valves

- Steel pistons

- Self-adjusting piston rod seals

This design ensures quiet and efficient handling of propane, butane, and anhydrous ammonia.

Even under the most demanding operating conditions, LB Series compressors provide the ideal combination of:

- Consistently high performance

- Energy efficiency

- Reliable operation

- Low maintenance costs

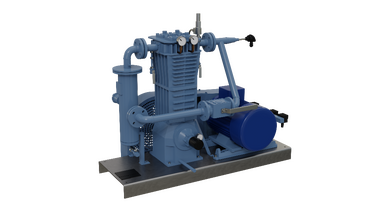

BLACKMER LB600-Serie – pistins gas compressors

Model: LB601, LB602

LB601 and LB602 – Two-Cylinder Piston Gas Compressors

The Blackmer LB601 and LB602 compressors are two-cylinder piston gas compressors with a capacity of 64.2 CFM at 825 RPM.

All BLACKMER LB compressors feature a robust and durable design:

- Cylinder head and cylinders made of ductile iron

- High-efficiency valves

- Steel pistons

- Self-adjusting piston rod seals

This construction ensures quiet and efficient handling of propane, butane, and anhydrous ammonia.

Even under the most demanding operating conditions, LB Series compressors provide the ideal combination of:

- Consistently high performance

- Energy efficiency

- Reliable operation

- Low maintenance costs

BLACKMER LB940-Serie – pistons gas compressors

Model: LB942, LB943

BLACKMER LB940 Series – BLACKMEWR LB942 and BLACKMER LB943 Two-Double-Acting Cylinder Compressors

The BLACKMER LB940 Series, consisting of the BLACKMER LB942 and LB943 models, features two double-acting cylinders and delivers high capacity for liquids as well as gas compression of propane, butane, and anhydrous ammonia. These compressors are particularly suited for large-scale applications, such as barge, ship, and rail tank car unloading.

The compressors provide a capacity of 125.2 CFM at 825 RPM. Compared to competitors and other LB Series models, the LB940 compressors are equipped with thicker and more robust wear parts—including piston rings, connecting rod pins, needle bearings, and high-efficiency valves—allowing for longer operating intervals between maintenance.

Additionally, the compressors feature:

- Cylinder head and cylinders made of ductile iron

- Steel pistons

- Self-adjusting piston rod seals

The LB940 Series thus delivers maximum performance, energy efficiency, quiet operation, low maintenance costs, and high reliability, even under extremely demanding operating conditions.

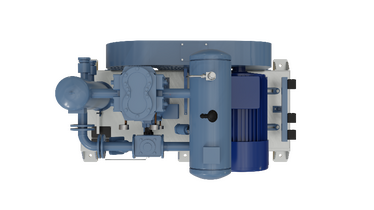

BLACKMER-PPTEC Compressor Units for Liquefied Gas

The BLACKMER-PPTEC compressor unit consists of the following main components:

The BLACKMER-PPTEC Compressor Unit consists of the following main components:

- Compressor: LB081, LB161, LB361, LB601, LB942

- Liquid separator

- Pressure gauge on the suction line

- Pressure gauge on the discharge line

- Safety valve on the discharge line

- Electric motor: Available in Ex e or Ex d version

- V-belt drive, including belt guard

- Steel frame and piping system

Optional process and piping equipment:

-

4-way ball valve piping, consisting of:

-

4-way ball valves

-

Strainer

-

Connecting piping

-

- Buffer tank (for LB942 compressors)

- Corrugated hoses (2 pcs)

Optional monitoring equipment:

- MIN pressure sensor on the suction line

- MAX pressure sensor on the discharge line

- Level sensor in the liquid separator

- MIN pressure sensor for oil pressure monitoring

- MAX temperature sensor on the discharge line

- Electrical control system in Ex or standard version