BLACKMER NP and BLACKMER X PUMPS for petrochemical applications

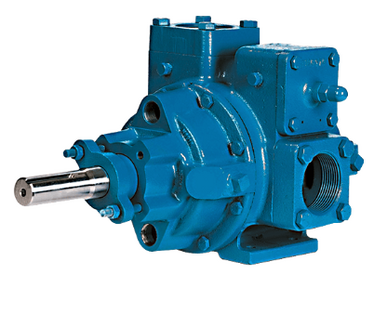

NP-Serie – rotary vane pumps

BLACKMER NP Series Rotary Vane Pumps with Self-Lubricating Bush Bearings for Maintenance-Free Operation

The NP Series rotary vane pumps, part of the Iron Line, were specifically designed to provide maximum versatility in handling clean, non-corrosive liquids. These all-purpose positive displacement pumps are ideal for applications involving high temperatures, high pressure, high viscosity, or special shaft sealing requirements where pumps with bush bearings are needed.

The key to the NP Series’ versatility is Blackmer®’s unique rotary vane rotor design, which ensures consistently high performance over a wide viscosity range. Slow rotational speeds and a non-pulsating flow minimize shear and agitation of the pumped medium.

Blackmer Head and Bearing System

The specially designed head and bearing system ensures long bearing life. A small, continuous flow of liquid from the pump’s discharge lubricates the bearings, forming a hydrodynamic film that minimizes temperature rise.

- Self-priming and briefly dry-run capable thanks to self-adjusting vanes

- Suitable for priming and line drainage

- High volumetric efficiency and symmetrical bearing support reduce power requirements compared to other positive displacement pumps, improving efficiency and lowering operating costs

Fully Integrated Unit Assemblies

PPTEC-ENERGY offers preconfigured, prefabricated complete systems as ready-to-use pump solutions.

These units include:

- Motor

- Gearbox or V-belt

- Baseplate

- Coupling guards

- BLACKMER NP stainless steel rotary vane pump

BLACKMER NP Series Pump Design and Features

- Ductile iron construction with metallized carbon bush bearings and non-metallic vanes for extended service life

- Optional commercial mechanical seal made of stainless steel, carbon, and PTFE

- Shaft stub compatible with most standard third-party mechanical seals

- Optional jacketed pump head for high-temperature operation

- Pump design minimizes shear and agitation of the medium

- Adjustable safety valve protects the pump from overpressure

Advantages of Blackmer Rotary Vane Technology

- Unique vane design automatically adjusts for wear, ensuring constant flow rates

- Excellent self-priming and dry-run capability

- Consistent performance and trouble-free operation

- Easy maintenance: vanes can be replaced without removing the pump from the piping system

- High suction capability and ability to drain lines completely

- Low maintenance requirements and reduced lifecycle costs

Applications of Blackmer NP Pumps

- Refined fuels

- Fats

- Solvents

- Chocolate

- Syrups

- Molasses

- Edible oils

- Black liquor

- Sodium silicate

- Tallow

- Wax

- Adhesives and glues

- Creosote-containing liquids

- Asphalt

- Aqueous Film Forming Foam (AFFF)

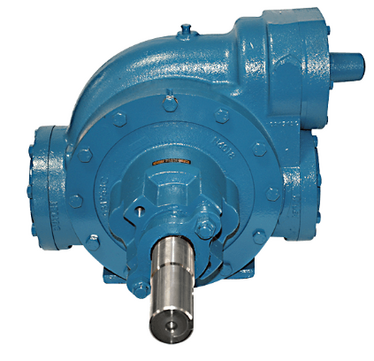

BLACKMER X-Serie – rotary vane pumps

Part of the Iron Line – Blackmer® General-Purpose Rotary Vane Pumps

The BLACKMER X Series rotary vane pumps belong to the Iron Line and are designed for general transfer applications.

- Connection sizes: 1 to 4 inches

- Flow capacity: 3 to 520 gpm (approx. 11–1,968 L/min)

- Temperature range: up to 300 °F (approx. 149 °C)

- Maximum pressure via safety valve: 125 psi (8.62 bar)

Only the BLACKMER XF1A and XF1PA models are designed for C-Face motor mounting.

The X Series pumps are self-priming, and the self-adjusting vanes help maintain this capability.

They are suitable for transferring clean, non-corrosive industrial liquids as well as fuel products, including a wide range of oils, solvents, and thinners.