CORKEN-PPTEC LPG compressor skids

CORKEN compressors for LPG

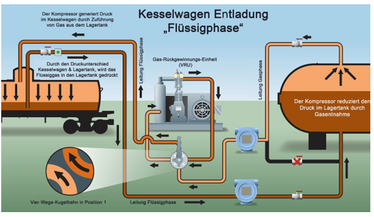

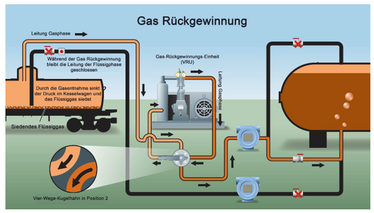

Many LPG systems (propane and butane) as well as pipeline systems for agricultural ammonia often do not provide ideal Net Positive Suction Head (NPSH) conditions. As a result, pumps frequently experience increased maintenance requirements.

Piston compressors, on the other hand, are operated solely with gases or vapors, so poor NPSH conditions do not affect their performance. Numerous pressurized LPG and ammonia vessels—such as tank cars or buried tanks—are equipped with top withdrawal connections. For liquid transfer in such applications, a piston compressor provides the ideal solution.

Most vertical LPG piston compressors from Corken feature single rod seals and are not designed for oil-free gas compression. The only exception is the CORKEN D891 model, which has two sets of seals (a V-ring seal and a segmented seal) but still does not operate oil-free.

Single-seal, non-oil-free compressors are typically used in non-corrosive and non-toxic applications where oil-free operation and leak containment are not critical. Typical applications include propane, butane, agricultural ammonia, and natural gas.

|

CORKEN compressors |

91 |

291 |

491 |

691 |

FD891 |

|

connecttion: |

|

|

|

|

|

|

Number of cylinder |

1 |

2 |

|||

|

piston strocke, mm |

63,5 |

63,5 |

76,2 |

101,6 |

101,6 |

|

piston displasement, m³/h |

13 |

28 |

58 |

100 |

200 |

|

Min suction pressure, bar |

0,21 |

||||

|

Max disharge pressure, bar |

23,1 |

31 |

|||

|

Motor, recomended, KW |

3,6 |

5 |

10 |

17-18 |

30-37 |

|

Weight bare compressor, kg |

68 |

96 |

177 |

338 |

410 |

|

Weight skid, aprx, kg |

225 |

283 |

385 |

650 |

1300 |

customized design always available

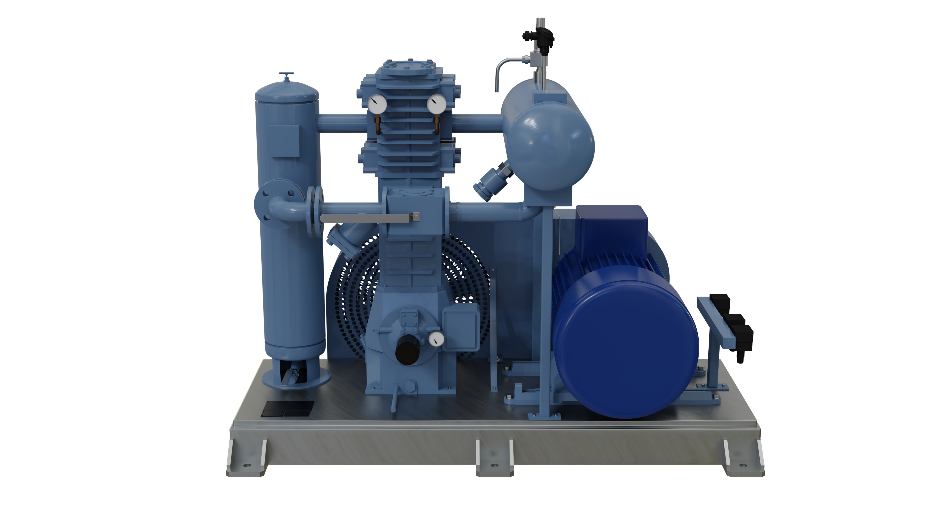

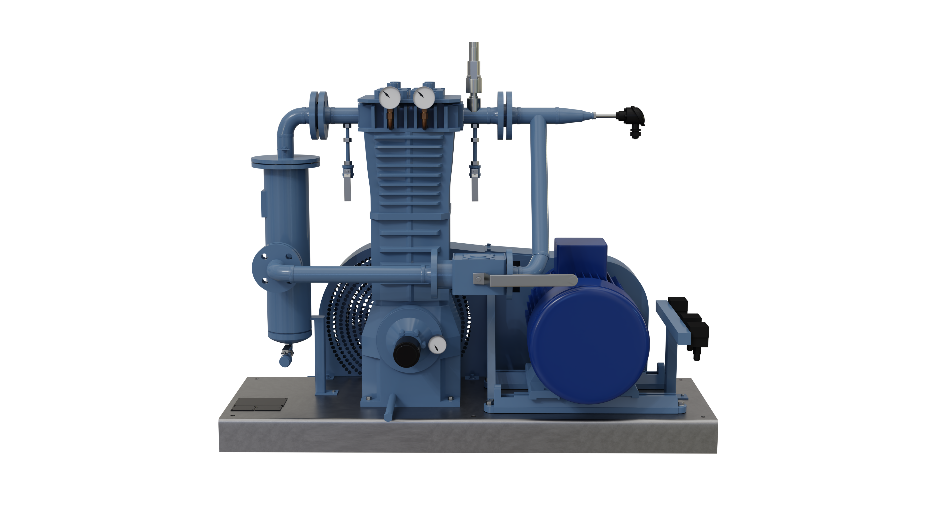

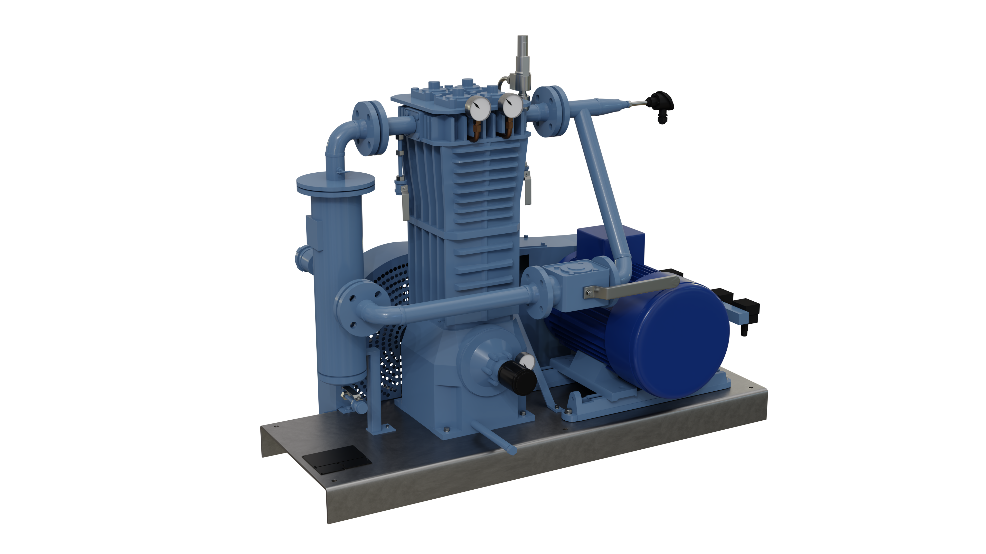

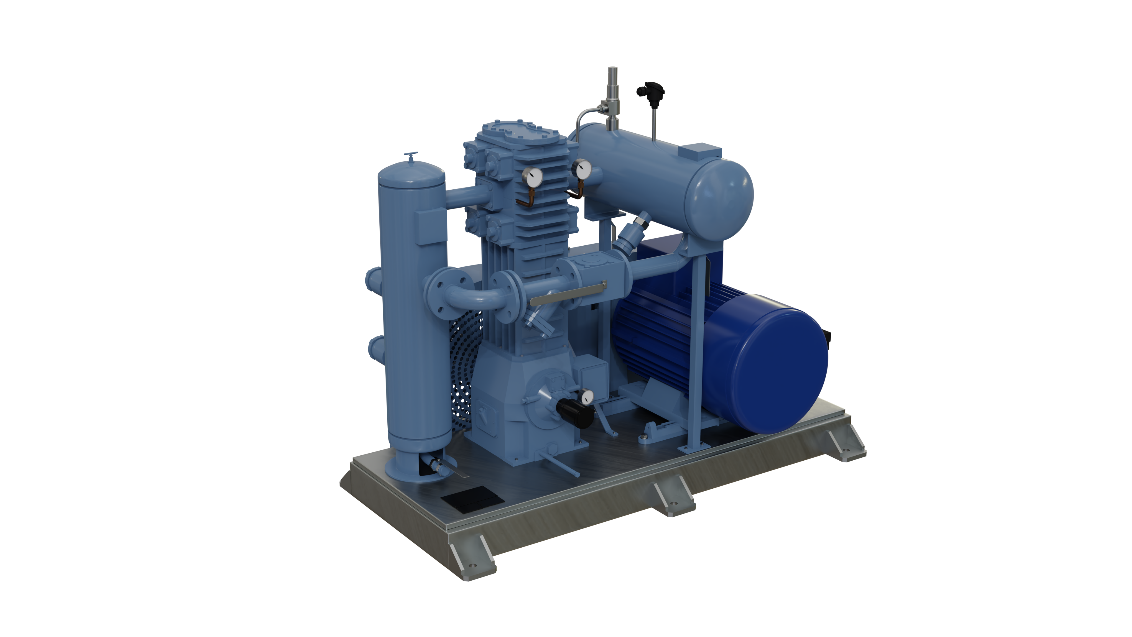

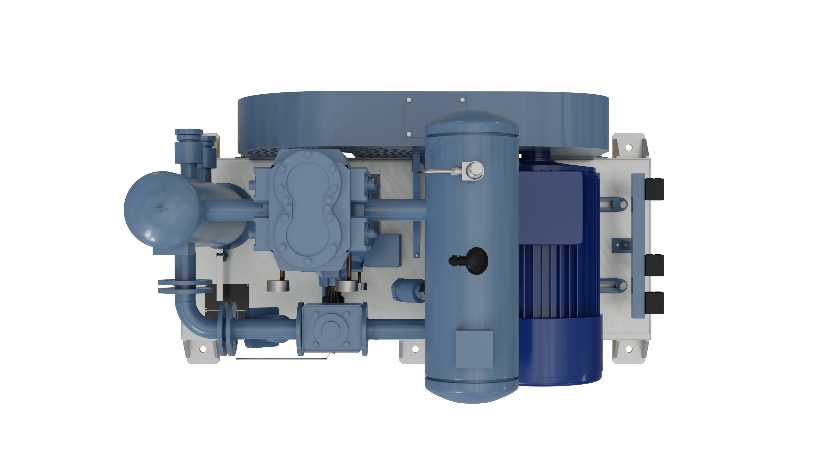

CORKEN-PPTEC compressor skids for LPG

The CORKEN-PPTEC Compressor Unit Consists of the Following Main Components:

- Compressor: 91, 291, 491, 691, FD 891

- Liquid separator

- Pressure gauge on the suction line

- Pressure gauge on the discharge line

- Safety valve on the discharge line

- Electric motor: Available in Ex e or Ex d version

- V-belt drive, including belt guard

- Steel frame and piping system

Optional process and piping equipment:

-

4-way ball valve piping, consisting of:

• 4-way ball valves

• Strainer

• Connecting piping - Buffer tank (for FD891 compressors)

- Corrugated hoses (2 pcs)

Optional monitoring equipment:

- MIN pressure sensor on the suction line

- MAX pressure sensor on the discharge line

- Level sensor in the liquid separator

- MIN pressure sensor for oil pressure monitoring

- MAX temperature sensor on the discharge line

- Electrical control system in Ex or standard version