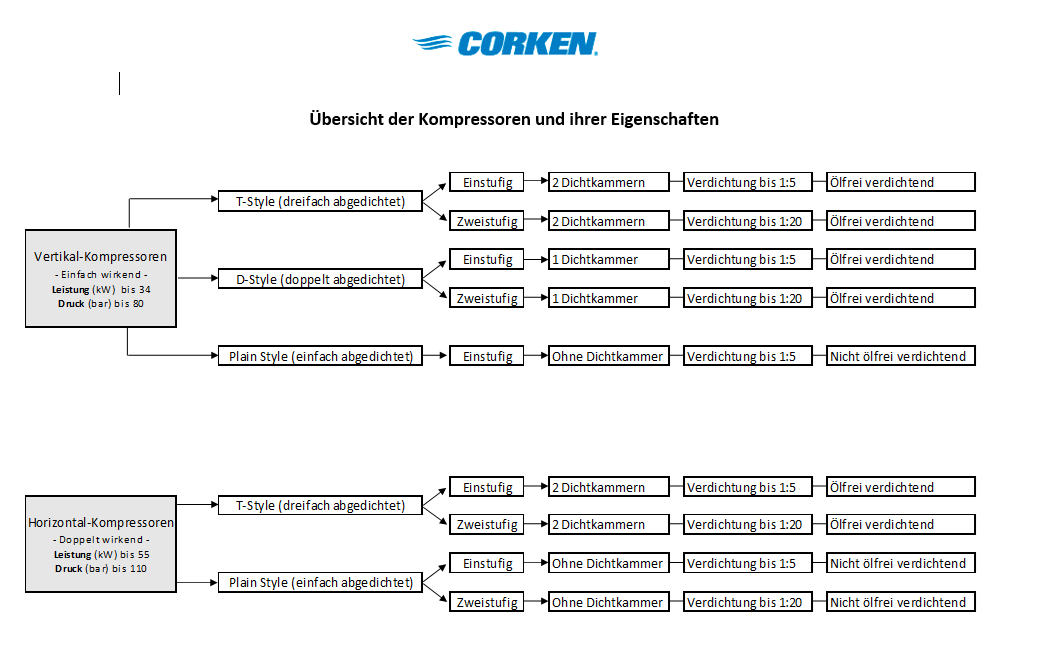

CORKEN compressors for industrial applications

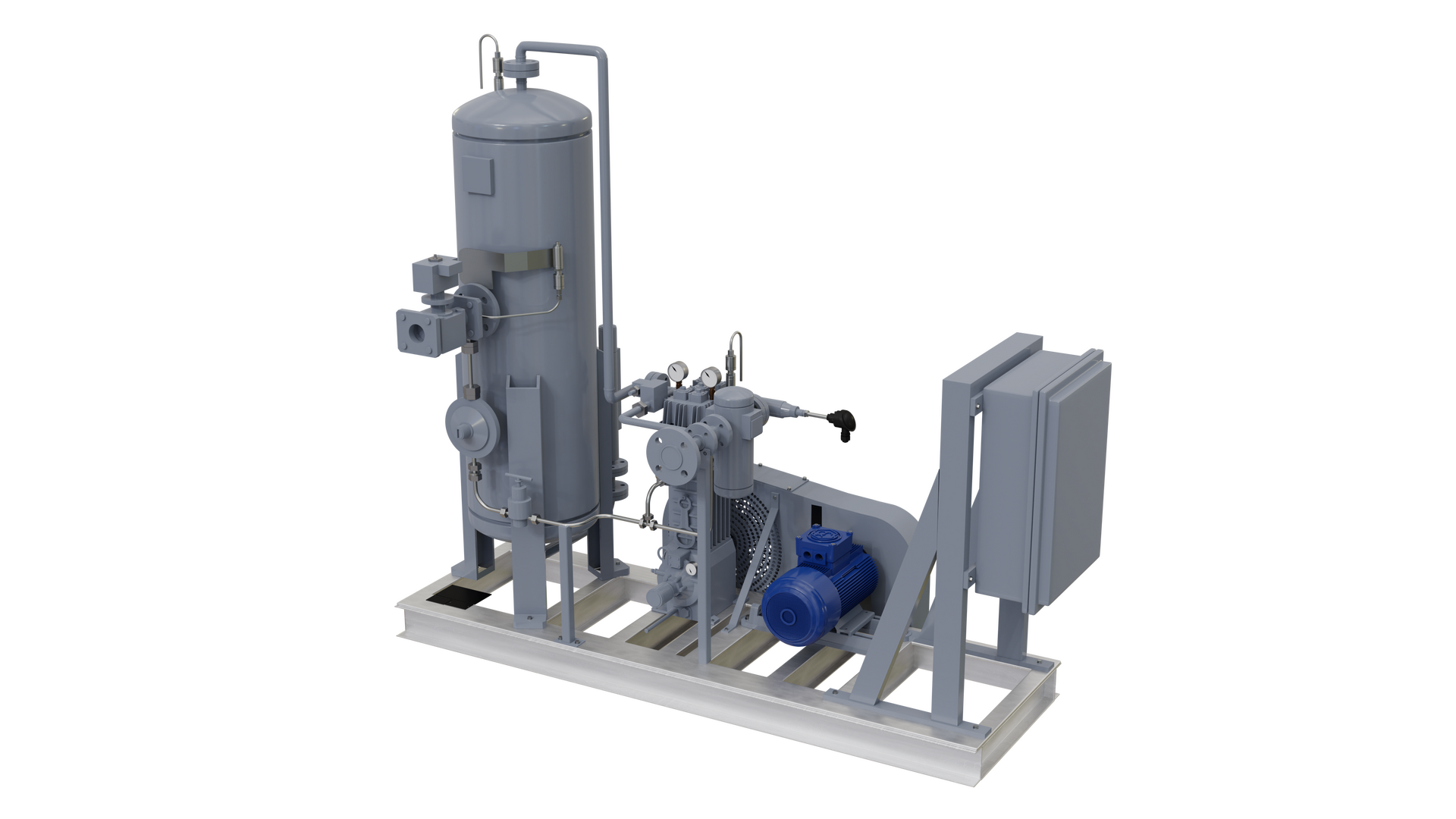

Industrial Vertical CORKEN Compressors

Corken Industrial Piston Compressors – Seal Configurations and Custom Solutions

Corken offers a wide range of piston rod seal configurations, spacer bar designs, and special coatings, suitable for a broad spectrum of industrial gases.

A double-sealed piston compressor (CORKEN D-Style) features a spacer bar and provides a medium level of leak containment.

A triple-sealed compressor (CORKEN T-Style) is equipped with two spacer bars and ensures the highest possible level of leak control. Each area between the seal sets can be flushed or pressurized as needed to achieve maximum leak containment.

Both designs are available as single- or two-stage compressors, air- or water-cooled, and single- or double-acting, with NPT connections or ASME Class 300 RF flanges.

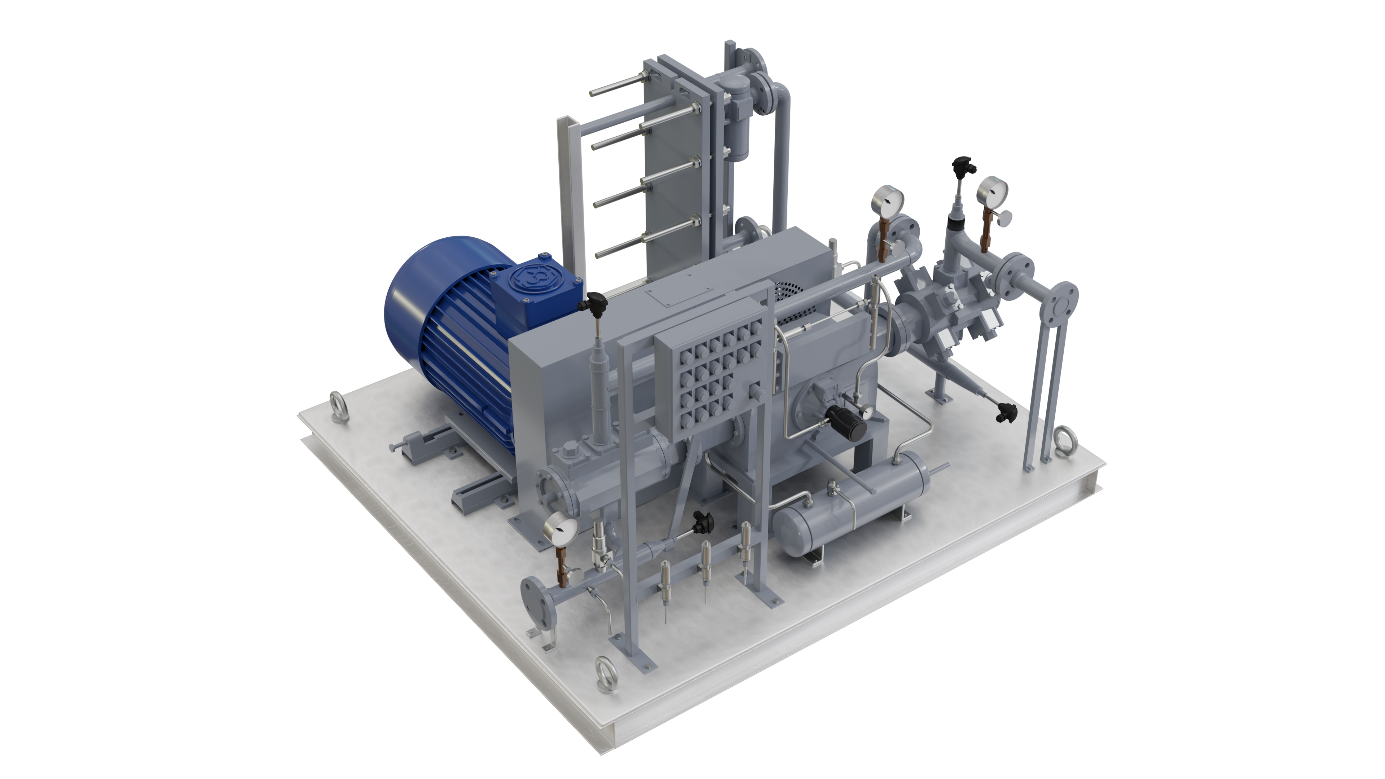

Standard compressor packages are available for liquefied gas transfer, vapor recovery, and gas booster applications.

If none of these standard solutions meet specific application requirements, PPTEC-ENERGY can provide a custom-engineered compressor package tailored to the client’s needs.

CORKEN Compressors Are Designed for Over 3,000 Applications and the Following Gases:

- 1-Butene / Deuterium Carbon Monoxide / n-Heptane

- 2,2-Dimethylpropane / Dimethylamine / Hydrocarbon Gas

- n-Hexane / Ammonia / Dimethyl Ether

- Krypton / n-Octane / Argon / Natural Gas

- Nitrous Oxide / n-Pentane / Benzene

- Ethane / Air / Neon / Biogas / Ethyl Chloride

- Methane / Ozone / Bromotrifluoromethane

- Ethylene / Methylacetylene / Phosgene / Butadiene

- Ethylene Oxide / Methyl Bromide / Propane / Carbonyl Sulfide

- Helium / Methyl Chloride / Chlorine / Hexafluoroethane

- Methyl Fluoride / Nitric Oxide / Chlorodifluoromethane / Isobutane

- Methyl Mercaptan / Carbon Tetrachloride / Hydrogen Chloride

- Isobutene / Monoethanolamine / Hydrogen / Cyclo-Isobutylene

- Monomethylamine / Cyanide / Cyclohexane / Carbon Dioxide / n-Butane

Refrigerants

- CFC-11 CFC-502 HFC-134A Vinylbromid

- СFС-12 CFC-503 HFC-152A Vinylfluorid

- СFС-13 HCFC-22 Schwefeldioxid Vinlchlorid

- СFС-113 HCFC-141B Schwefelhexafluorid Xeno

One stage CORKEN compressors

|

D-style |

D91 |

D291 |

D491 |

D491-3 |

D691 |

D691-4 |

D891a |

|

T-style |

T91 |

T291 |

T491 |

T491-3 |

T691 |

T691-4 |

T891a |

|

Cylinder Bore in mm |

|||||||

|

1 stage |

76.2 |

76.2 |

101.6 |

76.2 |

114.3 |

101.6 |

114.3 |

|

2 Stage |

- |

- |

- |

- |

- |

- |

76,2 |

|

piston strocke (mm) |

63.5 |

63.5 |

76.2 |

76.2 |

101.6 |

101.6 |

101.6 |

|

Pistons displacement m³/h |

7.0 |

13.9 |

29.7 |

16.7 |

50.1 |

39.6 |

96.3 |

|

14.3 |

28.7 |

61.2 |

34.5 |

103.3 |

81.6 |

198.8 |

|

|

MWAP (bar) |

23.1 |

23.1 |

23.1 |

41.4 |

23.1 |

41.4 |

31.0 |

|

max. power (kW) |

5.6 |

11 |

11 |

11 |

26.1 |

26.1 |

34 |

|

Maximum Piston Rod Load (kg) |

1,633 |

1,633 |

1,814 |

1,814 |

3,175 |

3,175 |

3,175 |

|

max. outlet temperatur (°C) |

177 |

177 |

177 |

177 |

177 |

177 |

177 |

|

weight (kg) |

68.0 |

95.2 |

176.9 |

176.9 |

337.9 |

337.9 |

408.2 |

|

ANSI/DIN Flansch Option |

JA |

JA |

JA |

JA |

JA |

JA |

– |

|

wather cooling as option |

– |

– |

– |

– |

yes |

yes |

– |

two stages CORKEN compressor

|

D-style |

FD151 |

D191 |

FD351 |

D391 |

WFD551 |

D590 |

FD591 |

D791a |

|

T-style |

FT151 |

T191 |

FT351 |

T391 |

WFT551 |

T590 |

FT591 |

T791a |

|

cylinder bore in mm |

||||||||

|

1 stage |

63.5 |

76.2 |

69.9 |

114.3 |

101.6 |

152.4 |

152.4 |

152.4 |

|

2 stage |

31,8 |

44,5 |

44,5 |

63,5 |

63,5 |

82,5 |

82,5 |

82,5 |

|

piston strocke (mm) |

63.5 |

63.5 |

76.2 |

76.2 |

101.6 |

101.6 |

101.6) |

101.6 |

|

pistons displacement m³/h |

4.76 |

7.0 |

7.0 |

18.9 |

19.7 |

44.5 |

44.5 |

89.0 |

|

10.0 |

15.2 |

14.4 |

38.7 |

42.1 |

91.7 |

91.7 |

179.8 |

|

|

MWAP (bar) |

82.8 |

41.4 |

82.8 |

41.4 |

69.0 |

23.1 |

41.4 |

41.4 |

|

max. power (kW) |

11 |

11 |

11 |

11 |

26.1 |

26.1 |

26.1 |

34 |

|

max. piston rod load (kg) |

1,633 |

1,633 |

1,814 |

1,814 |

3,175 |

3,175 |

3,175 |

3,175 |

|

max. temperature outlet (°C) b |

177 |

177 |

177 |

177 |

177 |

177 |

177 |

177 |

|

weight (kg) |

97.5 |

97.5 |

154 |

158.8 |

369.7 |

358.8 |

358.8 |

421.9 |

|

ANSI/DIN Flange Option |

JA |

JA |

JA |

JA |

JA |

– |

JA |

– |

|

Option wather cooling |

– |

– |

yes |

yes |

yes |

yes |

yes |

– |

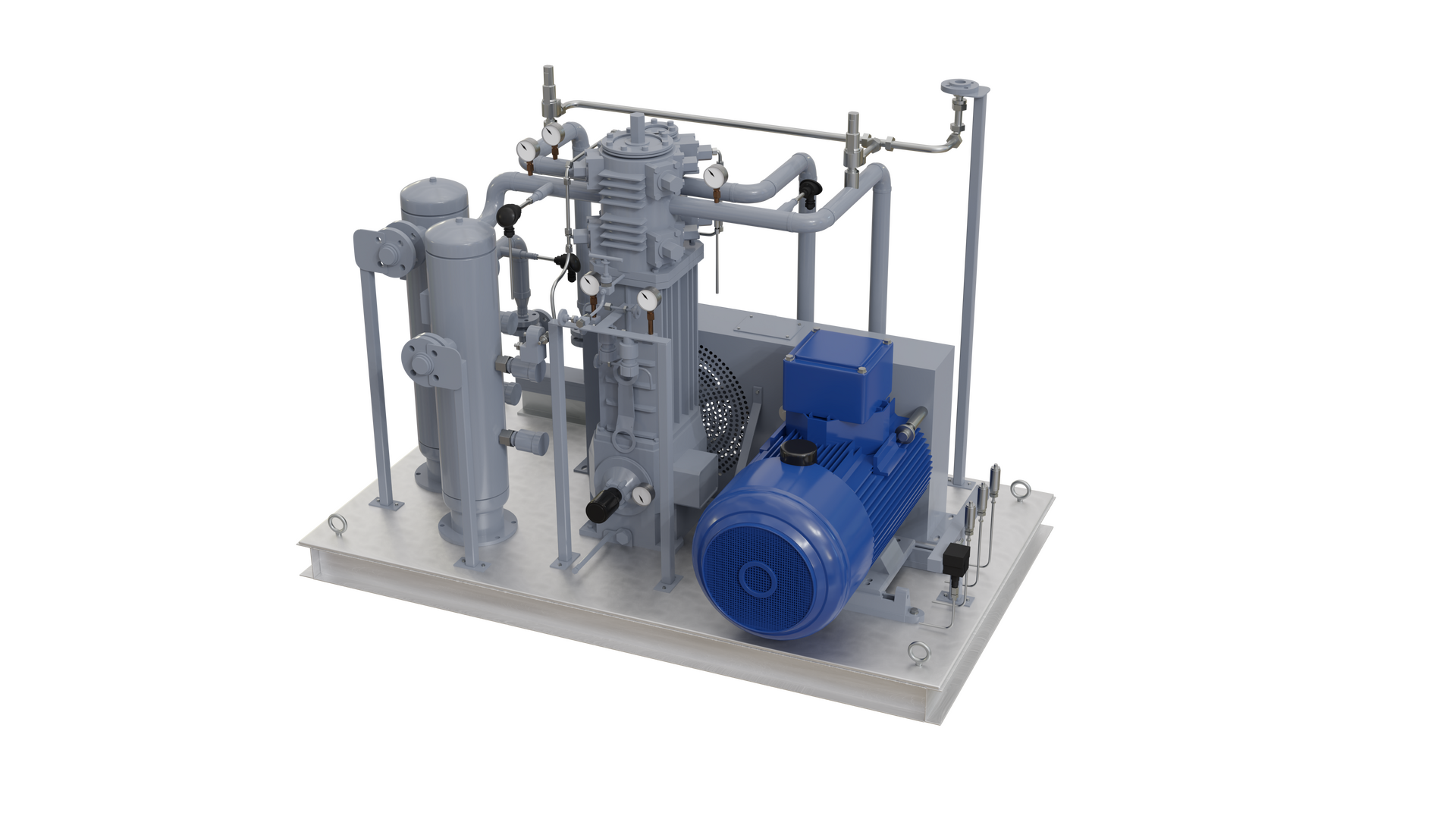

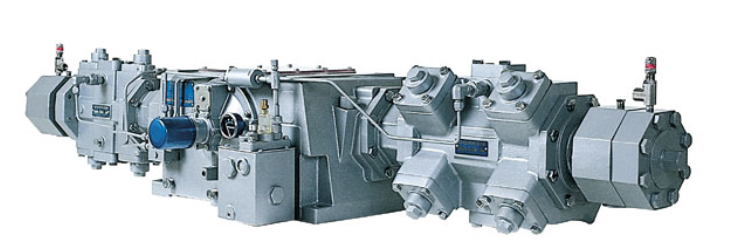

CORKEN Two-Stage Horizontal Piston Compressors

CORKEN horizontal Industrial Compressors

For High-Pressure and High-Capacity Applications

When the operating pressures and/or capacities of your application exceed the capabilities of Corken’s vertical compressors, horizontal compressors are the better choice. For the cylinder arrangement in horizontal industrial compressors, an opposed cylinder design (similar to a boxer engine) is preferred. These compressors can generate pressures up to 113 bar, with a piston displacement ranging from 12.9 to 704 m³/h.

Thanks to their design, these compressors operate very quietly and smoothly, and they also offer the flexibility to change cylinder sizes. Available cylinder bores include:

- 203.2 mm (8")

- 152.4 mm (6")

- 127 mm (5")

- 101.4 mm (4")

- 82.4 mm (3.25")

- 69.9 mm (2.75")

These cylinders can be configured in various single- or two-stage versions according to your requirements. Both lubricated models and dry-running compressors are available.

These horizontal compressors are offered as:

-

T-Style (THG600)

|

Zweizylindermodelle |

THG602AB |

THG602AC |

THG602AD |

THG602BC |

THG602BD |

THG602BF |

|

Größe |

8" x 6" |

8" x 5" |

8" x 4" |

6" x 5" |

6" x 4" |

6" x 2.75" |

|

Hubvolumen (m³/h) |

||||||

|

400 upm |

116.9 |

116.9 |

116.9 |

65.2 |

65.2 |

65.2 |

|

1200 upm |

351.7 |

351.7 |

351.7 |

195.4 |

195.4 |

195.4 |

|

Gewicht in kg (ca.) |

||||||

|

HG Modell |

449.1 |

444.5 |

440.0 |

421.9 |

406.0 |

399.2 |

|

THG Modell |

494.4 |

489.9) |

485.4 |

467.2 |

451.3 |

444.5 |

|

Zweizylindermodelle |

HG602BE |

HG602CD |

HG602CF |

HG602DE |

HG602DF |

HG602EF |

|

Größe |

6" x 3.25" |

5" x 4" |

5" x 2.75" |

4" x 3.25" |

4" x 2.75" |

3.25" x 2.75" |

|

Hubvolumen (m³/h) |

||||||

|

400 rpm |

65.2 |

44.9 |

44.9 |

28.5 |

28.5 |

18.3 |

|

1200 rpm |

134.4 |

134.4 |

134.4 |

84.6 |

84.6 |

54.5 |

|

Gewicht in kg (ca.) |

||||||

|

HG Modell |

399.2 |

399.2) |

393.3 |

390.1 |

390.1 |

383.3 |

|

THG Modell |

444.5 |

444.5 |

438.6 |

435.5 |

435.5 |

428.7 |

|

Ausführung |

Zylinder Code |

|||||

|

A |

B |

C |

D |

E |

F |

|

|

Zylinderbohrung |

203,2 |

152,4 |

127 |

101,6 |

82,6 |

69,9 |

|

Maximaler Arbeitsdruck (bar) |

20,7 |

24,1 |

51,7 |

69 |

82,8 |

113,8 |

Allgemeine Daten

|

Max. Hubweg (mm) |

76,2 |

Max. Ausgangstemperatur (°C) |

176,7 |

|

Max. Belastung der Kolbenstange (kg) |

3175 |

Min. Arbeitstemperatur (°C) |

-31 |

|

Max. Motorenleistung (kW) |

55,9 |

Drehzahlbereich (UPM) |

400 - 1200 |